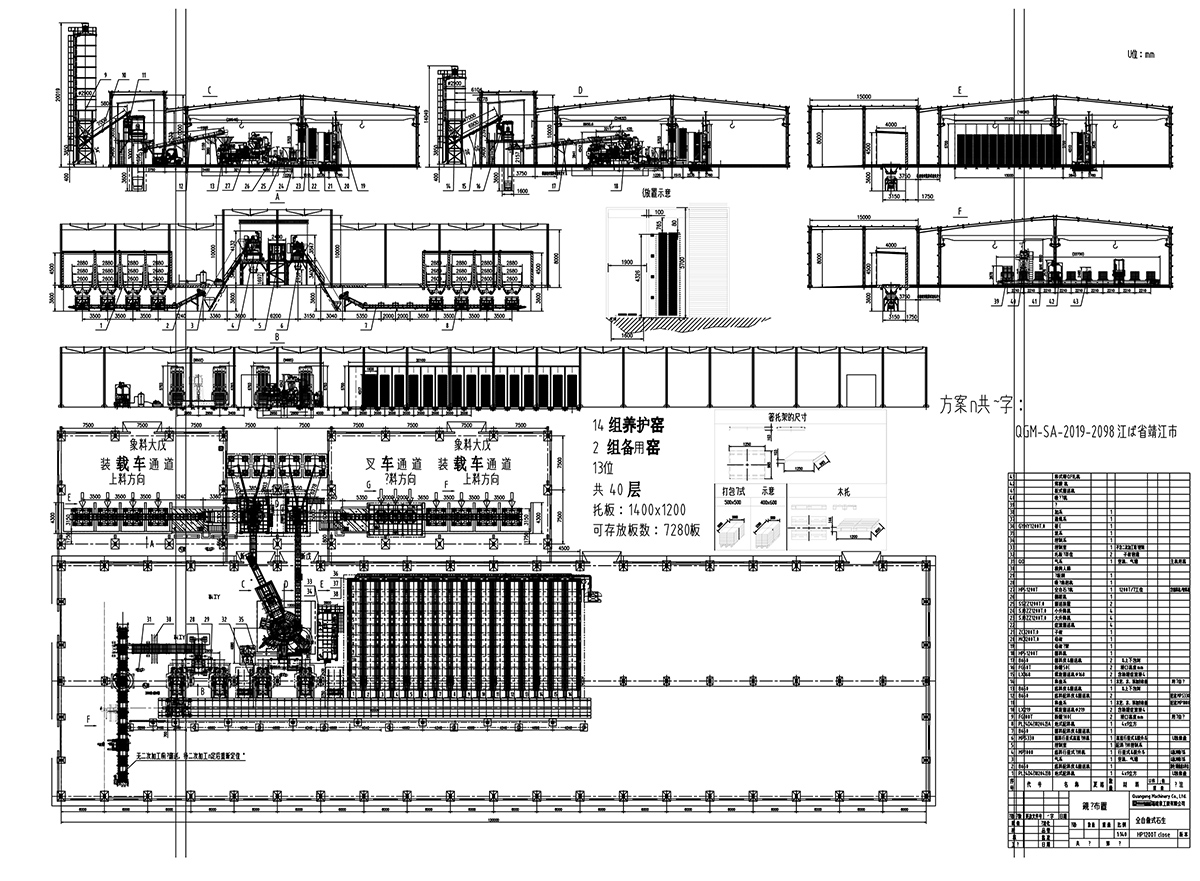

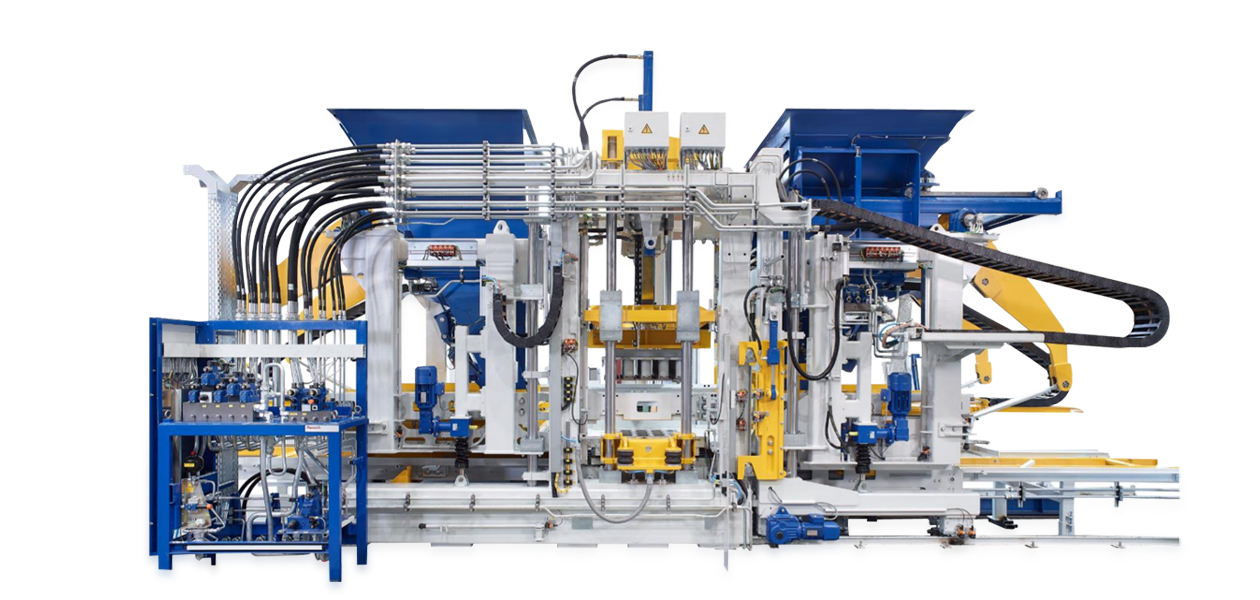

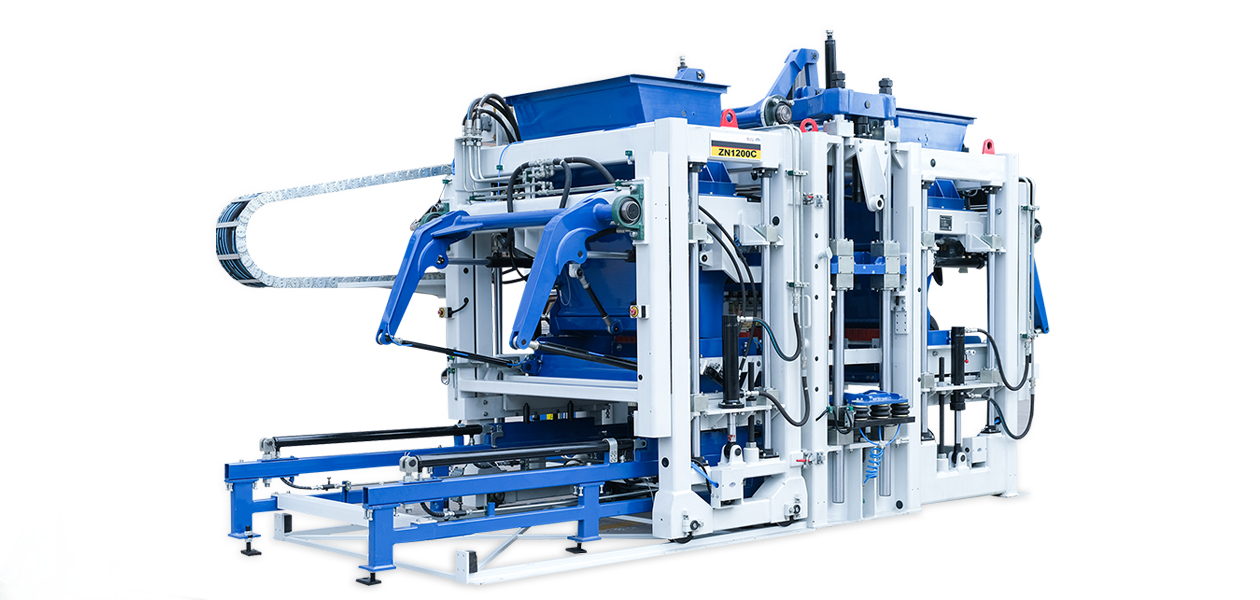

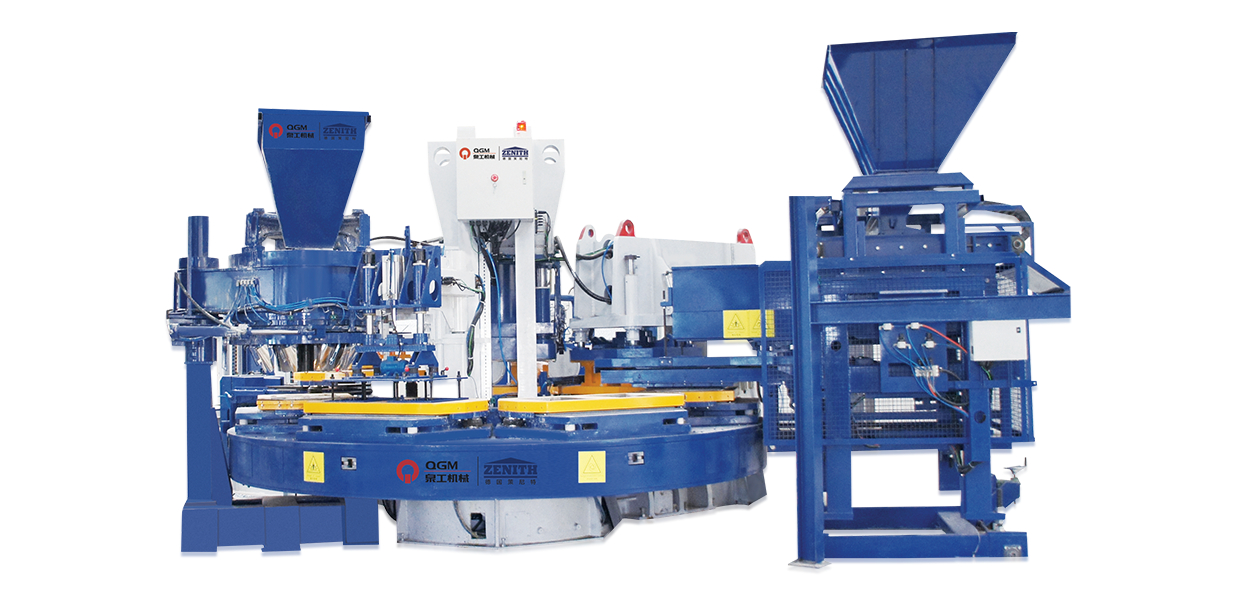

HP-1200T Hermetic Press Machine

HP-1200T Hermetic Press Machine

1.Prefill valve with a large flow, guarantees the output of a super high pressure and the quick movements and reactions.

2.The hydraulic station adopts a variable pump, which regulates speed and pressure through a proportional valve, which can save energy and easy to operate.

3.The large slewing bearing is used in the turntable, which is controlled by a servo motor with an encoder, to achieve stable operation and precise control.

4.Adopt advanced visual control system, PLC adopts SIEMENS S7-1500 series.

5.The facemix filling device has a built-in planetary mixer, which uses a quantitative turntable, and the amount of filling is accurate and stable each time.

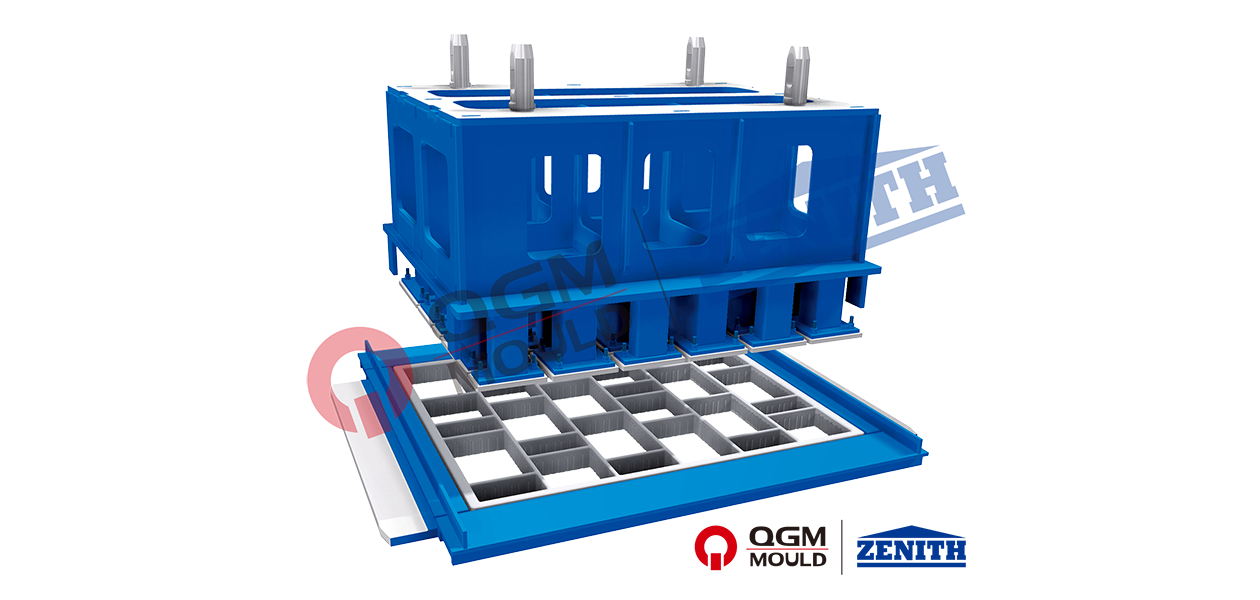

6.The base material filling device can quantitatively control the base material amount through a variety of transition devices, and then control the height of the finished brick, which greatly saves the number of molds.

Technical Parameters

| Type | HP-1200T |

| Numbers of work station | 7 |

| Block Arrangement(Example) | 900×900(1pcs/mould) |

| 500×500(2pcs/mould) | |

| 400×400(4pcs/mould) | |

| Max. Block Height | 80mm |

| Max. Main Pressure | 1200t |

| Main Pressure Cylinder Bore | 740mm |

| Weight (include a set of mould) | about 90000kg |

| Power | 132.08kW |

| Cycle Time | 12-18s |

| Length x Width x Height | 9000×7500×4000mm |

-

- 1Facemix Filling Station

- 2Facemix Distribution Station

- 3Service Station (Changing-mould)

- 4Bacemix Filling Station

- 5Pre-pressing Station

- 6Main Press Station

- 7De-moulding Station