120

Have exported to 120

countries and regions

35

More than 35 Global

Service Branches

150

Over 150+ persons

R&D Team

40

More than 40+

production experience

200

More than

200 Engineers

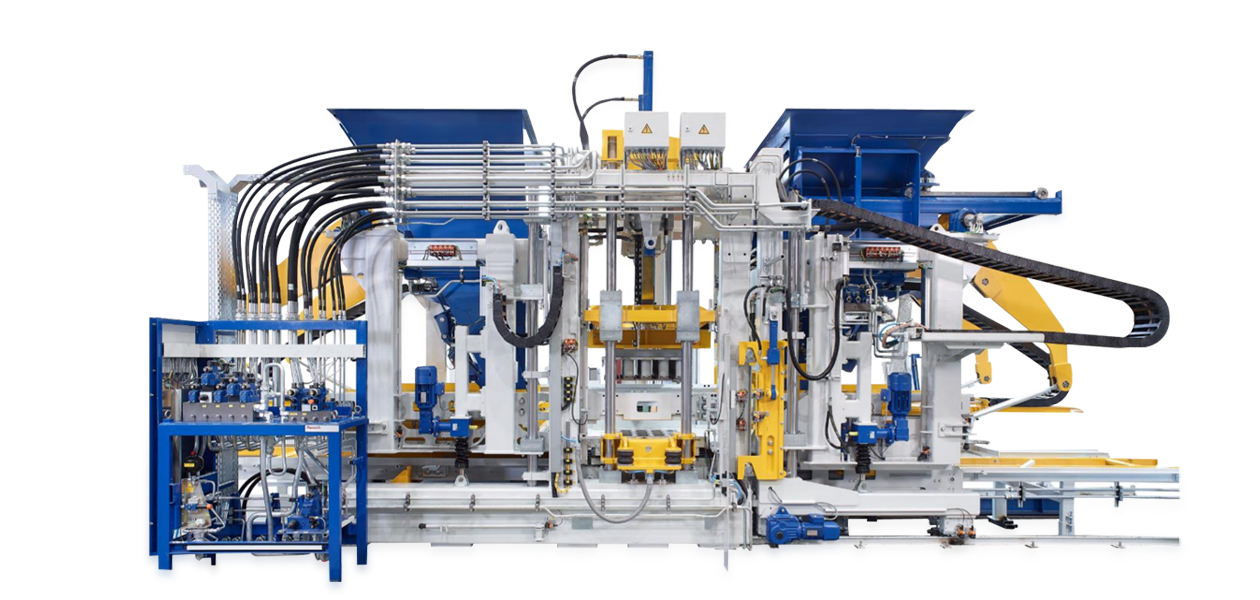

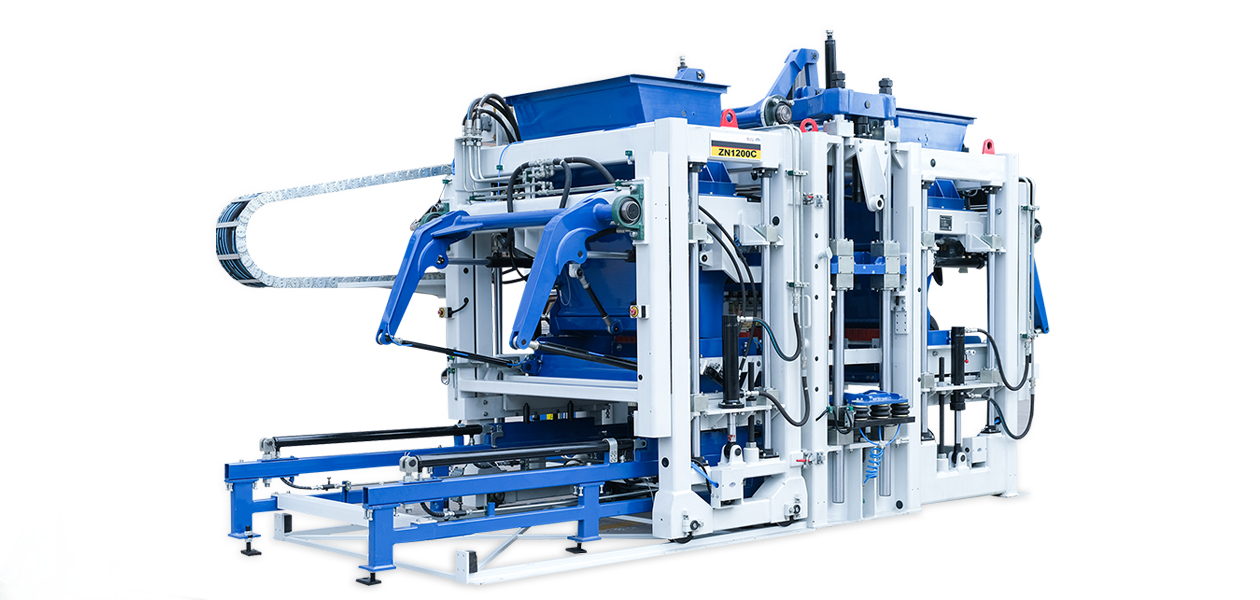

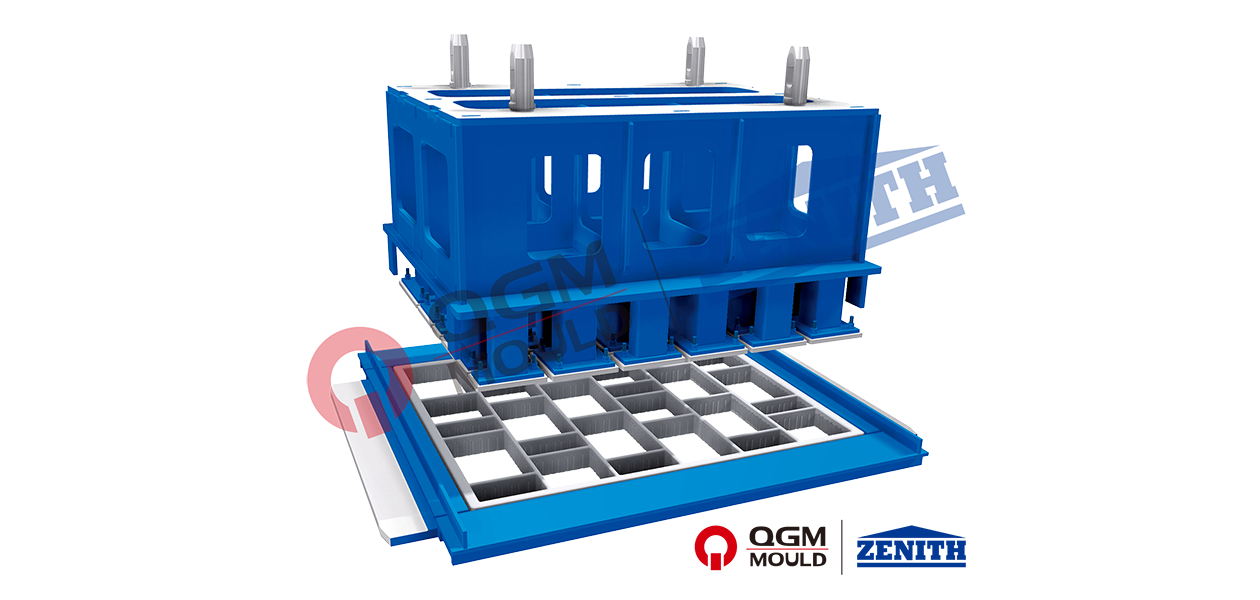

About Quangong

Quangong Machinery Co., Ltd, QGM in short, founded in 1979, is located in Quanzhou, covering an area of 60 acres and has a registered capital of 100 million CNY. It is a high-tech enterprise specializing in the research and development, manufacturing and sales of concrete block & brick making machine. QGM products cover a full range of automatic concrete block machine & brick making machine, providing management consulting services, technology upgrading, talent training and production trusteeship services for the industry. QGM has member companies of Germany Zenith Maschinenfabrik GmbH, India APOLLO-ZENITH Concrete Technologies Pvt. Ltd, & Quangong Mould Co., Ltd., with more than 200 engineers and technicians.

Intelligent Manufacturing

Green Factory, Green Manufacturing, Efficient Recycling & Utilization of Resources

Intelligent Workshop

CNC equipment interconnection - production status perception, accurate execution

Intelligent Workshop

CNC equipment interconnection - production status perception, accurate execution

learn moreDigital Production

Manufacturing ecological chain, production demands transparency

Cloud Platform Service

Intelligent networking technology, online diagnosis, feedback and maintenance

Cloud Platform Service

Intelligent networking technology, online diagnosis, feedback and maintenance

learn moreNews & Events

Learn More