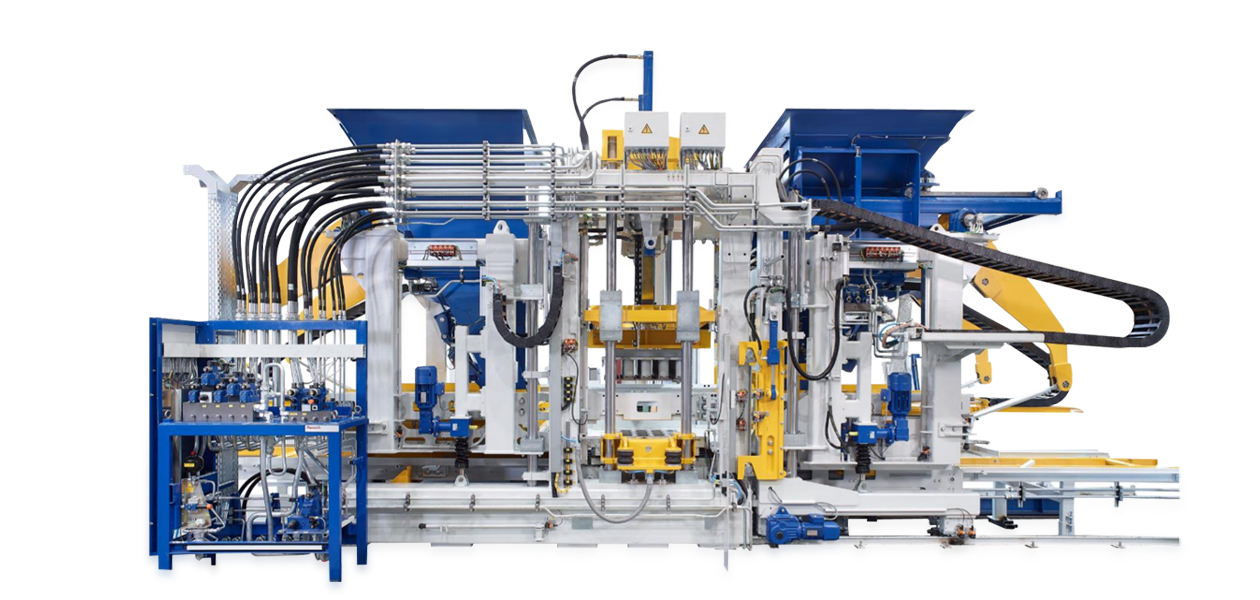

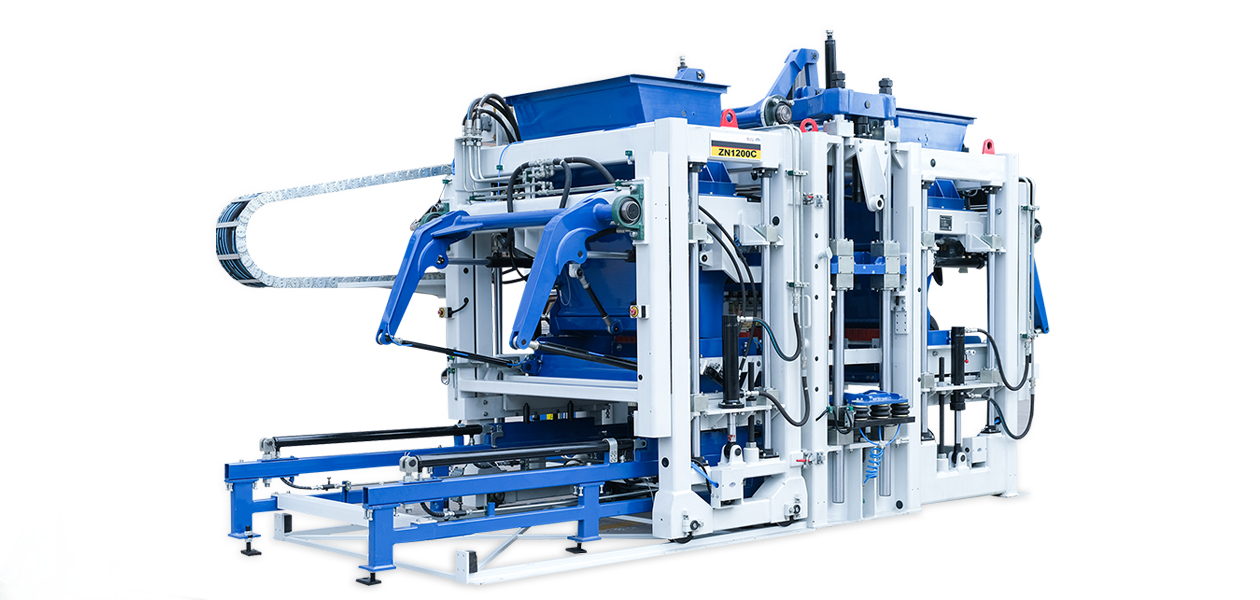

Zenith 940SC Pallet-Free Block Machine

Zenith 940SC Pallet-Free Block Machine

Zenith 940 is one of the most advanced block machine in the world, fully automatic mobile multilayer production. It integrates various functions and can mass production for almost all concrete products, such as hollow block,solid bricks, paver/interlock & curbstone in the market.

Universal High-efficiency Production Equipment

Fully automatic mobile multi-layer production equipment-Zenith 940, It is one of the most advanced equipment of its kind in the world. It integrates multiple functions and can produce almost all concrete products such as hollow blocks, interlock, curbstone and permeable bricks used in the market on a large scale. It is the most competitive star product with high productivity, high efficiency and low failure rate.

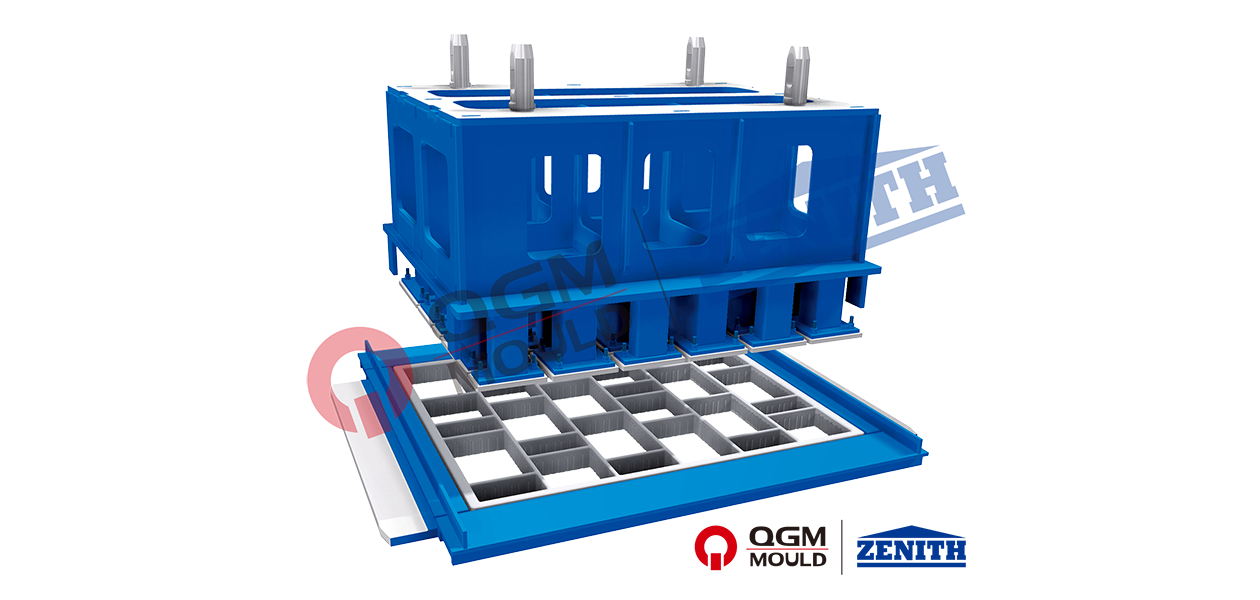

This machine has international advanced technology and can produce a variety of non-standard special products that cannot be produced by single pallet equipment. It can produce high-quality concrete cable trays, maintenance wells, prefabricated parts and other special products on a large scale in the most economical way. The length of products can reach 1.2 meters and the height can reach 1 meter.

The equipment has good adaptability to raw materials, and can meet the requirements of taking industrial waste residues such as solid waste and fly ash as raw materials on a large scale. The multi-layer production function of the equipment has great advantages, and the wet block stack can be directly maintained and then packaged, thus eliminating many intermediate transfer processes.

|

Characteristic |

|

|

Base-mix hopper (forklift hopper loading) |

1200L |

|

Base-mix hopper (Fly bucket loading) |

2000L |

|

Face-mix hopper (forklift hopper loading) |

800L |

|

Face-mix hopper (Fly bucket loading) |

2000L |

|

Max. loading height of loading truck |

2800mm |

|

Forming area |

|

|

Max. forming area |

1240*1000mm |

|

Max. forming width (ground production) |

1240mm |

|

Product height |

|

|

Multilayer production |

|

|

Min. height of product (produced on pallet) |

50 mm |

|

Max. height |

250 mm |

|

Max. stacking height (pallet + first layer product height) |

640 mm |

|

Low Production (production on pallet) |

|

|

Max. height |

600 mm |

|

Low Production (production on the floor) |

|

|

Max. height |

650 mm |

|

Directly produced on the floor |

|

|

Max. height |

1000 mm |

|

Min. height |

250 mm |

|

Machine weight |

|

|

Total weight of machine |

15.5 T |

|

Machine Dimensions |

|

|

Total length (excluding face-mix device) |

4400 mm |

|

Total length (including face-mix device) |

6380 mm |

|

Maximum total height |

3700 mm |

|

Minimum total height (transport height) |

3240 mm |

|

Total width (including control panel) |

2540 mm |

|

Vibration system |

|

|

Max. table vibration force |

80 KN |

|

Max. upper vibration force |

40 KN |

|

Energy consumption |

|

|

According to the maximum number of vibration motors |

48 KW |

- 1Cement Silo

- 24-bins Batcher for Main Material

- 32-bins Batcher for Facemix

- 4Mixer for Main Material

- 5Mixer for Facemix

- 6Fully-automatic Block Making Machine

- 7Forklift

- 8Loader

- 9Shuttle Car

- 10Material Stocking Area

- 11Finished Product Area

- 12Four-sides Block Clamp

-

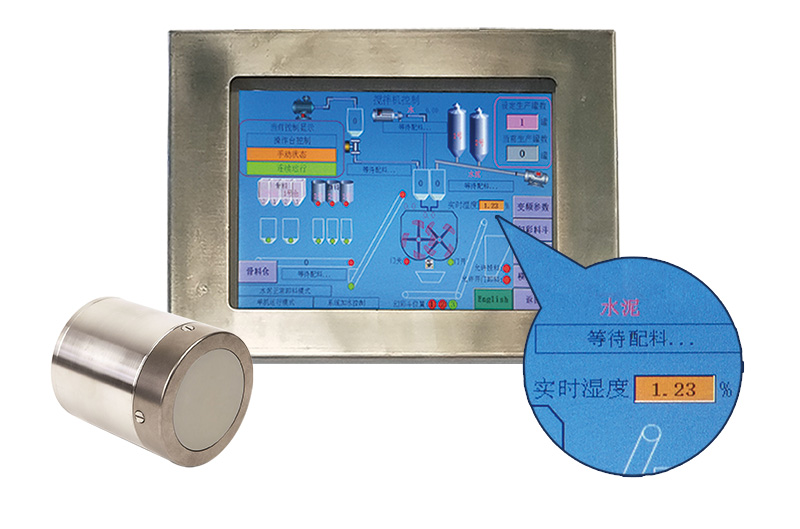

Batcher

-

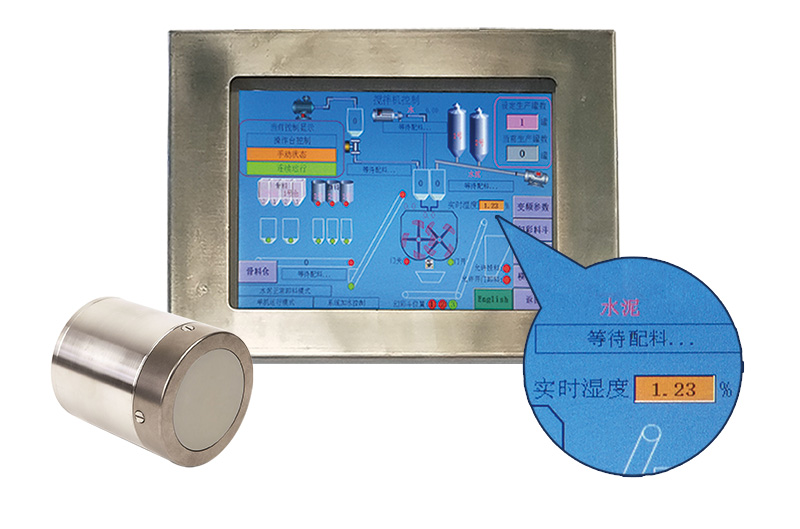

Moisture sensor