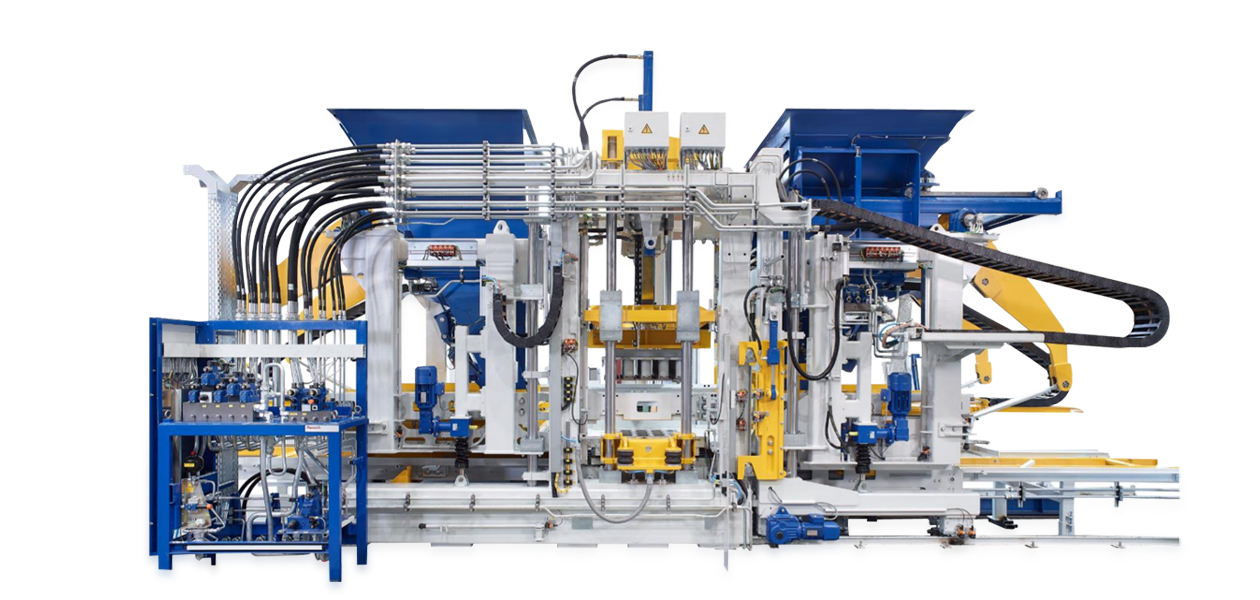

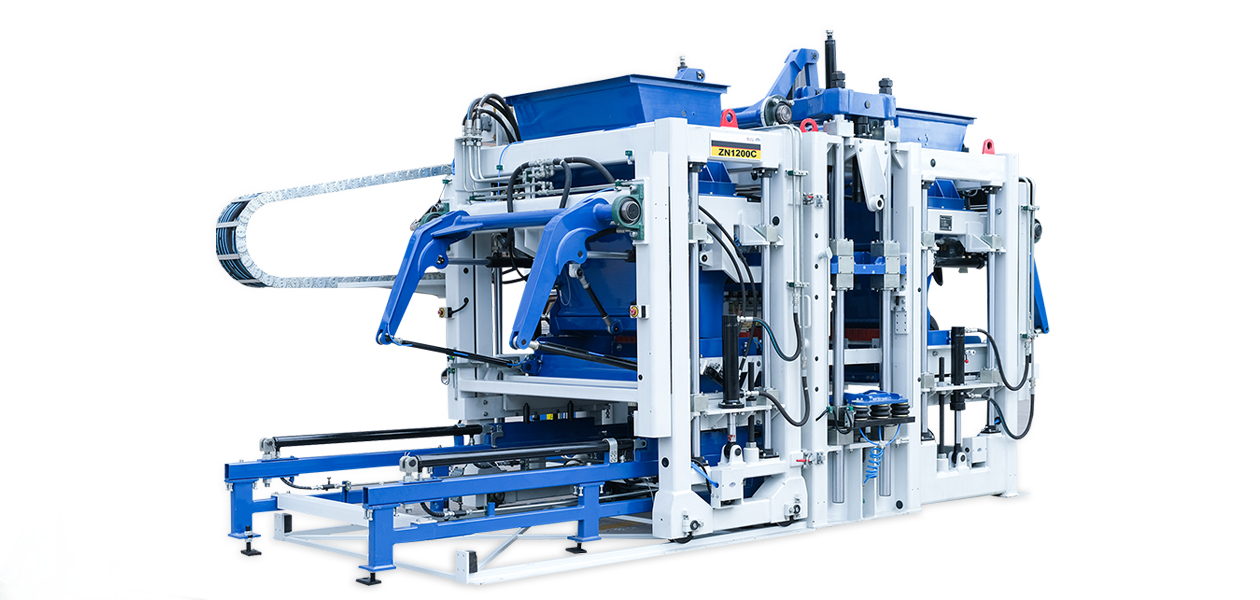

Zenith 1500-2 Automatic Block Making Machine

Zenith 1500-2 Automatic Block Making Machine

Zenith 1500-2 is the top-level intelligent production equipment newly developed by Zenith, which can produce various standard concrete products, such as hollow block, paving block, interlock, paving stone & road kerbs etc..

Zenith 1500-2 stationary single pallet block machine is the latest top intelligent production equipment developed by Germany Zenith, which can produce various standard concrete products such as hollow block, interlock, curbstone and solid bricks, as well as various special concrete products & can almost meet the needs of all customers.

Zenith 1500 is also equipped with a variety of cutting-edge intelligent equipment and systems, such as the latest control and automatic diagnosis system, servo vibration system, etc., which can give all-round support to operators. In addition, various convenient and practical programs are included to control expansion devices or equipment, such as automatic rapid mold change system, various color batching equipment and indenter cleaning equipment, etc., so as to improve production efficiency and product quality.

|

Product Height |

|

|

Max: |

500mm |

|

Min.: |

50mm |

|

Cubing Height |

|

|

Max. Production Area (produced on standard size pallets) |

1320*1150mm |

|

Size of Pallet (standard) |

1400*1200mm |

|

Thickness of Steel Plate |

14mm |

|

Thickness of Wooden Pallet |

50mm |

|

Base-mix Material Bin Volume (Excl. face-mix hopper) |

2500L |

|

Machine Weight |

|

|

With Face-mix Device |

36T |

|

Machine Dimensions |

|

|

Max. Total Length |

8500mm |

|

Max. Total Height |

4885mm |

|

Max. Total Width |

3300mm |

|

Machine Technical Parameters/Energy Consumption |

|

|

Vibration System |

Servo Vibration System |

|

Vibration Table |

Max.175KN |

|

Upper Vibration |

Max.35KN |

|

Hydraulic |

|

|

Total Flow |

540L/min |

|

Working Pressure |

160bar |

|

Max. Power |

160KW |

-

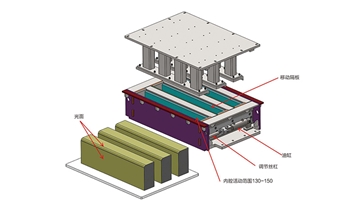

Zenith "Ultra-dynamic" servo vibration technology "Ultra-dynamic" servo vibration technology is a high-efficiency, self-adaptive vibration system specially designed for block machine; The servo motor can make the fastest response in the shortest reaction time, realize the highest vibration performance, reduce the cement consumption, shorten the production cycle, and produce high-density concrete products at the production place; Vibration system can adapt to the production requirements of different concrete products.

-

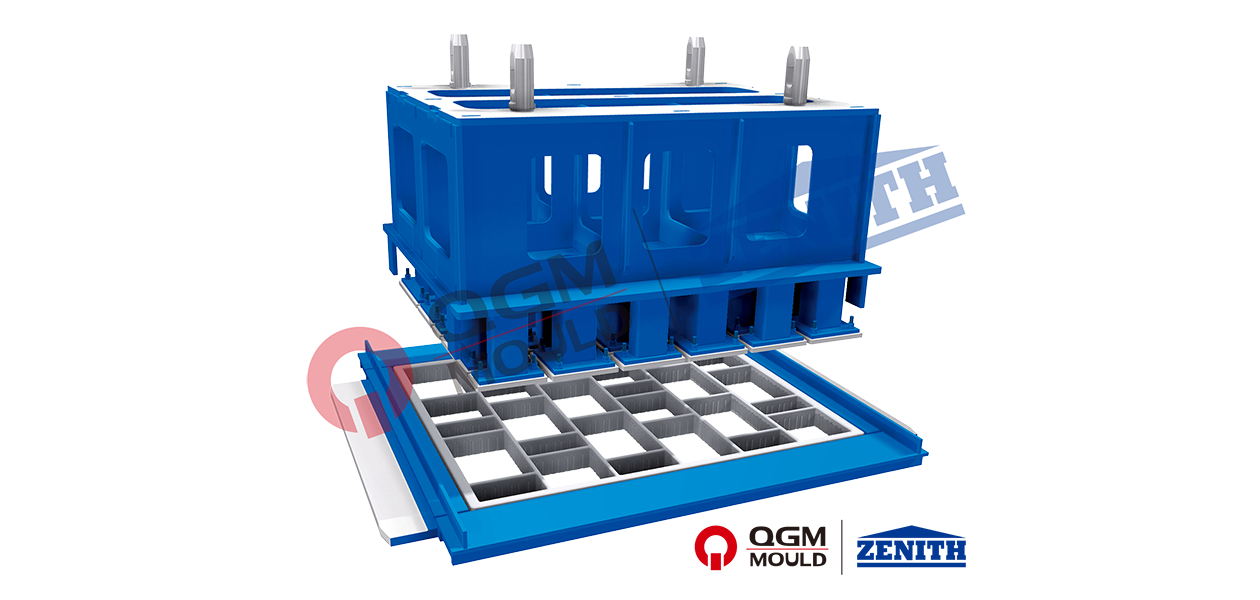

Accurate & quick mold changing system Automatic quick mold changing system is a system based on multi-device linkage and cooperation, which realizes rapid mold changing through intelligent system operation. When the mold is transferred to the main machine, the hoisting system realizes automatic mold change on the quick mold change device, and the tamper head and mold box are pneumatically clamped automatically; Safe, efficient, easy to operate and maintain, and the mold changing time is 10-15 minutes.

-

High precision servo hydraulic system The hydraulic system adopts high-end variable displacement pump and feedback servo valve system; Pressure, speed and position are closed-loop digital control, which can automatically adjust the flow and pressure of hydraulic pump. Independent oil temperature control system has high automation degree and precision, and the working efficiency can be improved by 10%-20%; It has the characteristics of energy saving, noise reduction, high efficiency and environmental protection.

-

Fully integrated automatic control system Adopt the most advanced automatic control platform of Siemens TIA-Portal series PLC in the world; It has faster, more precise and more stable operation ability and anti-interference ability. Flexible output through platform control technology can avoid fierce impact action of equipment and prolong service life of equipment. Visual display and diagnosis of human-computer interaction system and control system signals greatly facilitate operation and work.

-

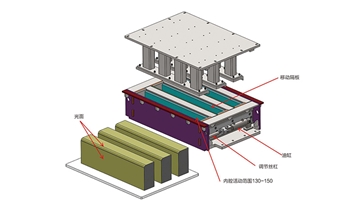

Intelligent feeding system The feeding system adopts the patented feeding technology of 360 rotary stirring, and the stirring group is equipped with simulation calculation stirring rollers, which can intelligently adjust the feeding mode according to different specifications of molds; Realize the uniformity and efficiency of feeding; It can be more suitable for the best feeding mode of special materials such as construction waste and tailings; With cylinder scraping and blowing device, it can avoid the influence of aggregate residue on fabric color, and make the surface color of products more beautiful.

-

Accurate servo control system Through signal feedback, the phase and speed of vibration are controlled, and the synchronization is high; High-speed standby and high-frequency operation can shorten the cycle time by 1.5 s with high efficiency; The servo controller is a book-type single-axis motor module, and the driver adopts a common DC bus connection mode (renewable energy can be utilized and recycled), which can reduce energy consumption by 15%; The braking effect is better.

-

German Version of High-quality Frame Design The main frame adopts the high-strength welded frame structure designed by Zenith brick machine technology, which is welded by customized special section steel. The design is reasonable, the welding is uniform and beautiful, and the whole frame is treated by aging vibration to ensure the high quality and high stability of the frame. The advanced structural design process makes the main machine expandable, and the side mold opening and closing function cabinet, board drawing (core) function and polystyrene board implantation function can be added later.

-

Leading intelligent cloud service system QGM&Zenith Intelligent Equipment Cloud Service Platform realizes online monitoring, remote upgrade, remote fault prediction and fault self-diagnosis, and equipment health status evaluation; Generate equipment operation and application status reports and other functions; Remote services can quickly diagnose and solve problems for users. Everything is interconnected, and the production and operation of equipment can be seen through the network in every corner of the world.

-

Intelligent AR maintenance technology Based on the intelligent equipment cloud service platform, with advanced AR service glasses, the intelligent AR maintenance technical service of QGM can be constructed, which can realize the rapid location of fault errors and the real-time generation of solutions. By establishing a real-time link with the cloud service platform, online real-time voice and graphics communication and sharing between users, technicians and after-sales engineers can be realized, and "you are my eye" can be carefully created to build a remote expert-level "precise surgery" maintenance service.

-

Scalable automatic control system Expandable mechanical functional interfaces such as side mold opening and closing device (curbstone with colored surface layer), horizontal groove pulling device (water conservancy brick/interlocking hollow block) and foam conveying device (insulation block) are reserved, which can realize rapid matching of multifunctional new product production. The DCS PN data interface is reserved, which has strong scalability and can be compatible with the user's central control system; It can also realize the new requirements of users in the production process of equipment, and upgrade and optimize the software of equipment; To provide users with long-term value-added services.

-

Batcher

-

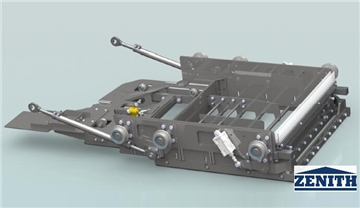

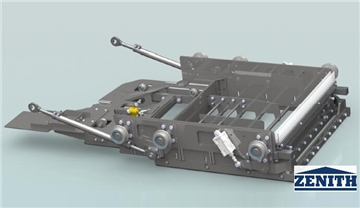

Automatic pallet feeder

-

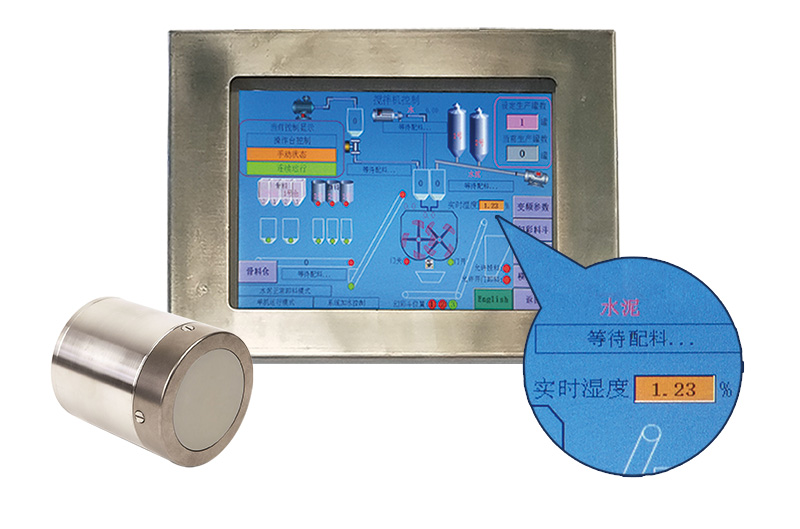

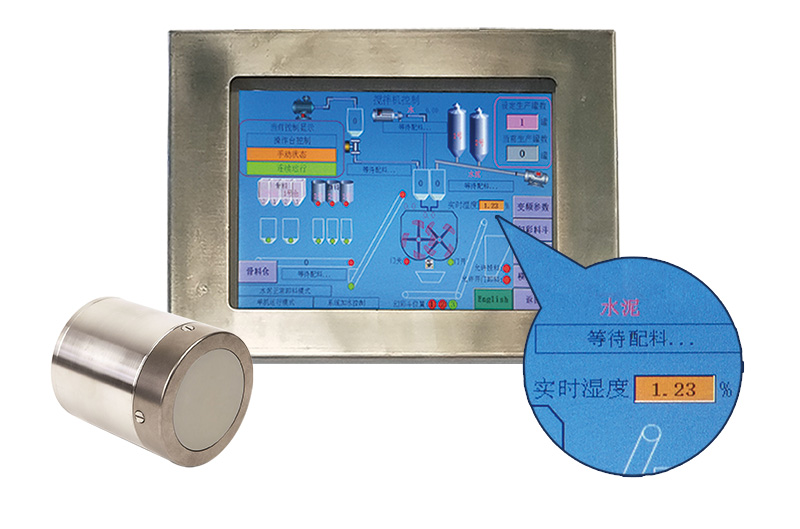

Moisture sensor

-

Finger car

-

Block-Pallet separator

-

Curing chamber

-

Block-pushing cuber