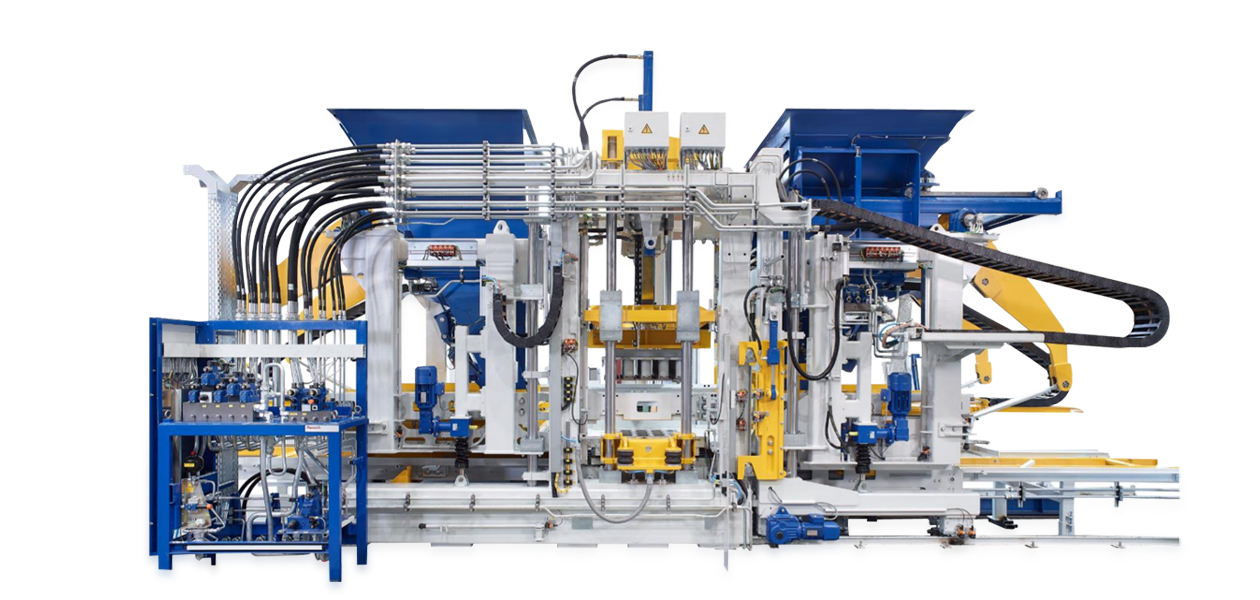

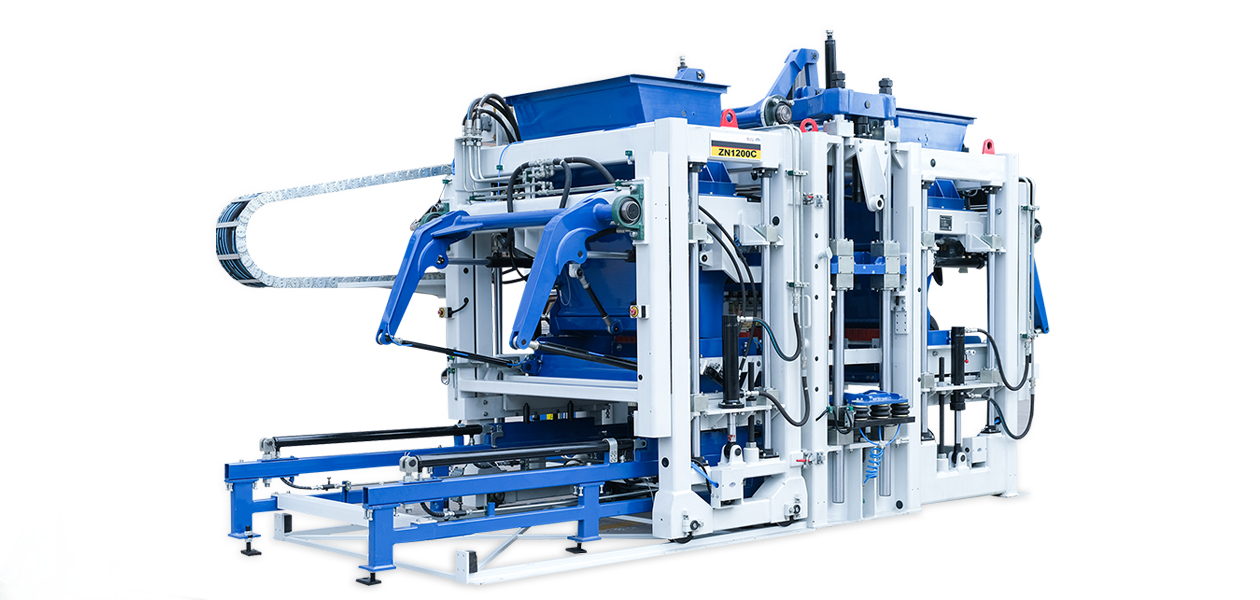

ZN1000C Concrete Block Machine

ZN1000C Concrete Block Machine

ZN1000C is an automatic block making machine, designed in Germany, made in China. There are 2x7.5kw SIEMENS frequency vibration motors in the bottom,2x0.55KW vibrators on top vibration, can achieve 100KN vibration force. The product height is ranging from 40mm to 300mm.

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

German Design - Higher Efficiency & Lower Failure Rate;

Made in China - Lower Cost & Better service.

ZN1000C block machine adopts German technology, the leading technology for block machine in the world. German technology is known for its rigor and simplicity, paying more attention to the overall performance, efficiency, and machine quality.

ZN1000C block machines are produced in China, strictly accordingly to German technology and craftsmanship. Compared with other brand of block machines, ZN1000C machines have more stable performance, higher production efficiency and lower failure rate. In terms of performance, efficiency, energy-saving, environmental protection, etc., it is far ahead of other block machines in the market.

|

Forming Area |

1100×820mm |

|

Height of Finished |

50-300mm |

|

Cycle Time |

15-25S (as per mould) |

|

Vibration Force |

80KN |

|

Pallet Size |

1200x870x(12-45)mm |

|

Production per Mold |

390x190x190mm(10pcs/mold) |

|

Bottom Vibration |

2x7.5KW(SIEMENS) |

|

Top Vibration |

2x0.55KW |

|

Electrical Control |

SIEMENS |

|

Power |

42.25KW |

|

Total Weight |

8T(Without Facemix) |

|

Dimension |

6145x2650x3040mm |

-

SIEMENS Frequency Vibration Technology QGM SIEMENS frequency conversional technology was re-innovated and improved by Germany R&D center. The block making vibration adopts low frequency standby, high frequency operation, which improve the running speed and product quality. At the same time, it reduces the impact on the mechanical parts and motor, prolongs the machine and motor lifespan, saving about 20%-30% of electricity when compared with the traditional motor.

-

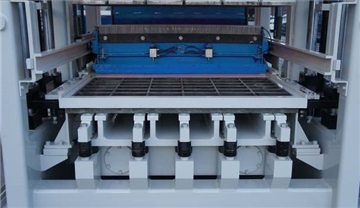

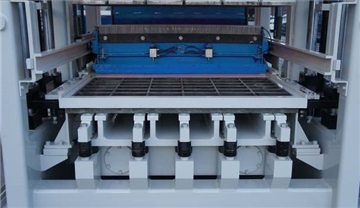

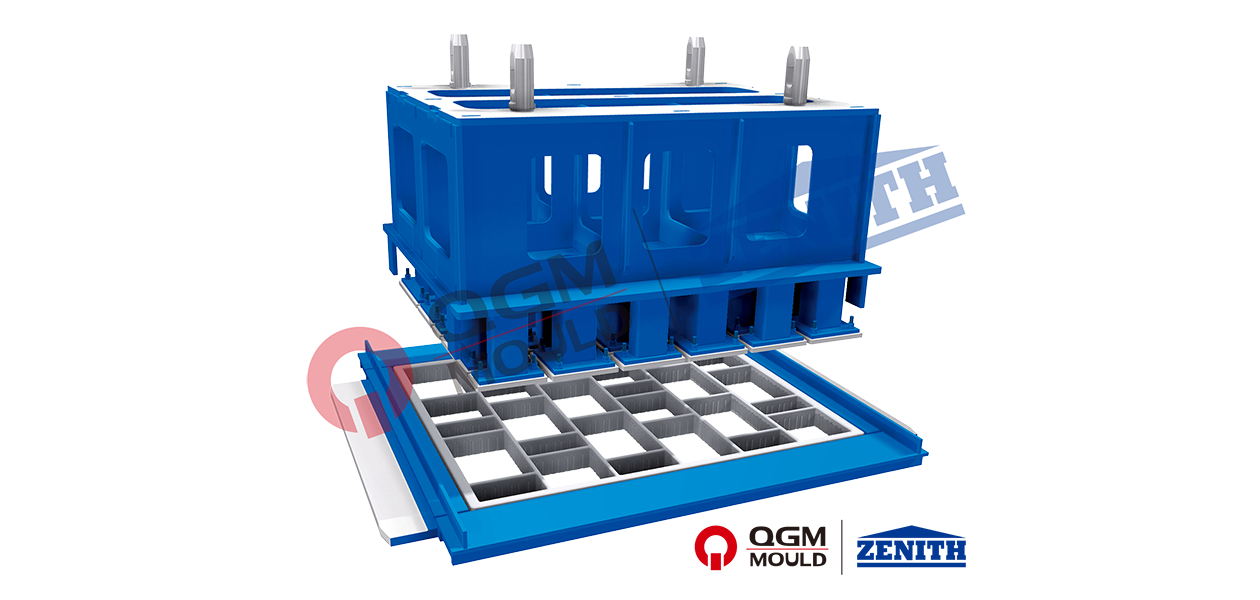

Double Vibration System Vibration table adopts high-duty Sweden HARDOX steel, consisting of dynamic table & static table, which can greatly improve the vibration efficiency. While there are another two vibrators on top, to increase compaction & guarantee the high quality of concrete blocks.

-

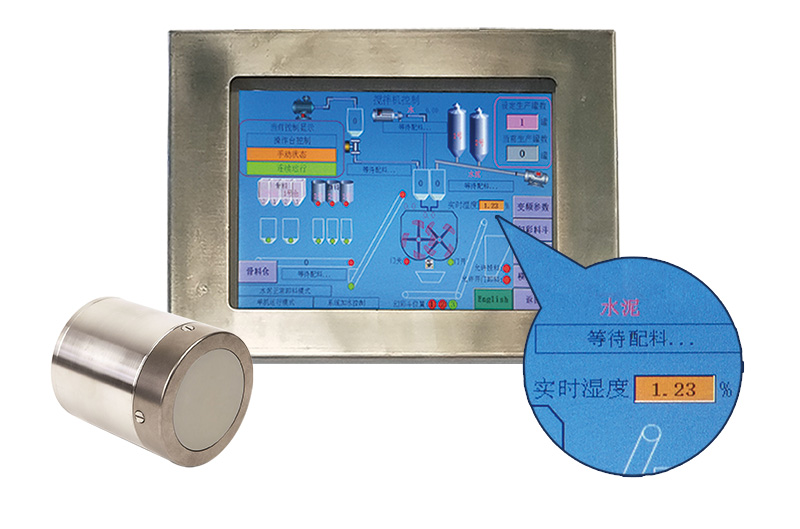

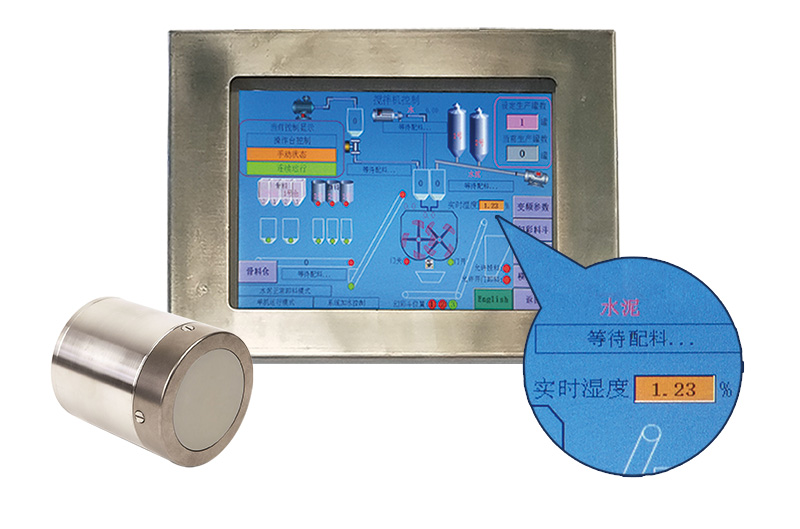

SIEMENS Intelligent Control System QGM control system adopts SIEMENS PLC, Touch Screen, contactors & buttons etc., which perfectly combine the automatic technology and advanced system from Germany. SIEMENS PLC has automatic trouble-shooting function for easy maintenance & also automatic-locking to avoid mechanical accidents caused by operational mistakes. While the SIEMENS touch screen can display real-time production status & achieve easy operation by visualization representation. In case any part is broken in the future, the replacement part can be sourced locally, which can save a lot of time & cost.

-

High-efficient hydraulic system The hydraulic motor is SIEEMSN brand, valves are Italy-brand & the hydraulic pipes are Italy-made ALFAGOMMA. Adopt double high-dynamic proportional valve and constant output pump, which can adjust the oil flow and pressure automatically, with the features of high-stability, high-efficiency and energy-saving.

-

Intelligent Cloud System for Remote Control QGM intelligent equipment cloud system realizes online monitoring, remote upgrade, remote fault prediction and fault self-diagnosis, equipment health status evaluation; generates equipment operation and application status reports and other functions; with the advantages of remote control & operation, quick troubleshooting & maintenance for the clients. Everything is interconnected, and the production and operation of equipment can be seen through the network in every corner of the world.

-

Batcher

-

Automatic pallet feeder

-

Moisture sensor

-

Finger car

-

Block-Pallet separator

-

Curing chamber

-

Block-pushing cuber

.jpg?x-oss-process=image/resize)

.jpg)